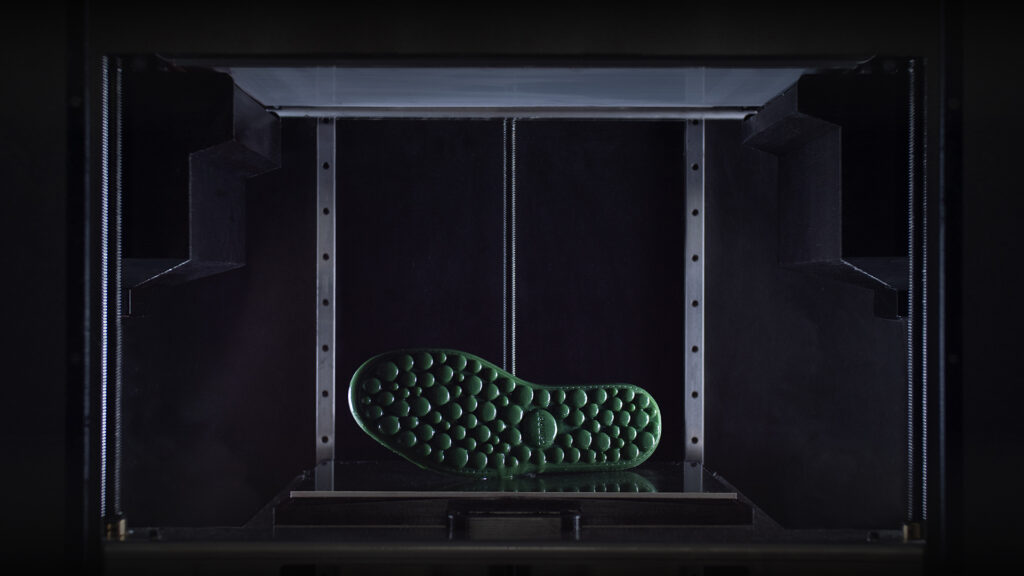

Our recently-released Viscous Lithography Manufacturing (VLM)™ is a patented breakthrough lithography-based 3D printing process that laminates thin layers of high viscosity resins. In this white paper, we get into the chemistry that provoked our decision to use such resins and shine a light on the benefits of doing so.

At the core of our Viscous Lithography Manufacturing (VLM)™ lies high viscosity resins. But what fuelled our decision to incorporate these types of materials? And what is it that pits this technology ahead of the other state-of-the-art resin machines in circulation now?

The content of this white paper will detail the science behind high viscosity resins, the benefits, and different formulation strategies – let’s take a look at an overview of what you can find within.

The benefits of VLM and how it overcomes traditional drawbacks

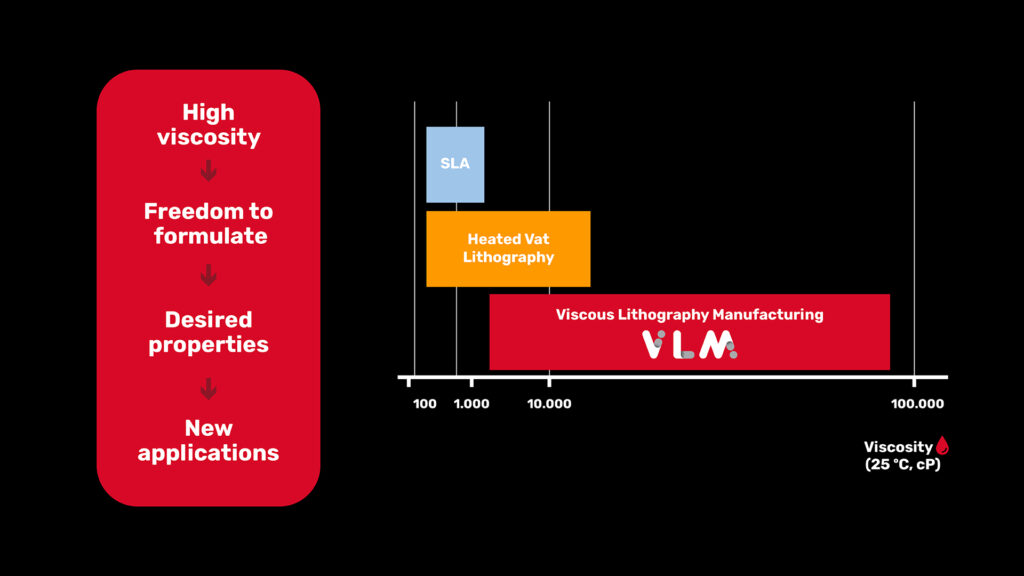

In general terms, the viscosity of a fluid strongly depends on the molecular composition of the formulation. Traditional resin-based 3D printing technologies, such as SLA or DLP, are restrained by their process limitations and constrained to a very narrow range of viscosities. To widen this range and to obtain better part properties, some printers heat up the entire resin vat up to 60ºC. However, this can entail some issues including the requirement of a conditioning time before starting volatile components of the resin being released into the air and reducing safety.

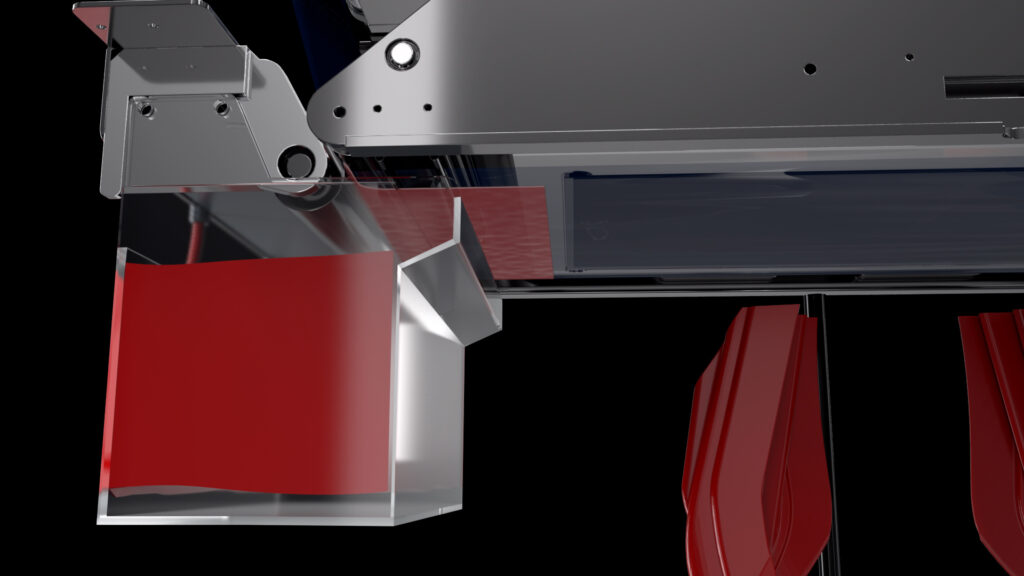

VLM solves this through the use of its powerful roller coater. This way, we can process the highly viscous resin at room temperature to perfectly laminate a thin layer of material on the top of the film in a mild and safe fashion. Since the layer thickness is always under control, only weak compression and peeling forces are generated on the part.

VLM technology is capable of handling resins up to 50 times more viscous than industry standards. VLM technology can easily manage a very wide range of viscosities, handling materials that would be impossible to print using traditional platforms, such as SLA or DLP.

Using formulation strategies to unlock new applications

In this white paper, we take a look at three new strategies made possible by VLM to enable better part performance:

1. Adding impact modifiers

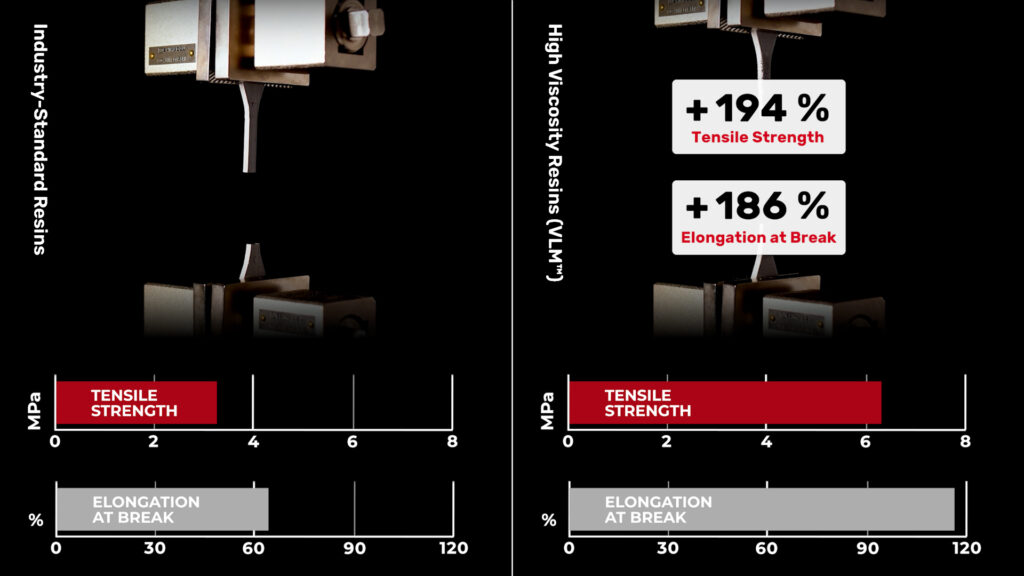

VLM’s capability of handling high viscosities allows the introduction of a big amount of impact modifiers into the mixture. This results in an optimal filler loading and advantages such as crack deflection, which improves the impact resistance and durability of rigid materials for 3D printing.

2. Using high molecular weight ingredients

Another viable approach you can follow when you no longer need to worry about your material’s viscosity is the introduction of major amounts of high molecular weight ingredients, such as oligomers. These ingredients, if employed in a big quantity, can greatly improve the overall behavior of the resin.

3. Reducing the amount of volatiles

By reducing the amount of volatiles, resins are safer and it is much easier to formulate and obtain biocompatible materials, which must comply with the very strict requirements of the biomedical sector.

Here, we’ve just touched upon the whys and hows of the benefits of VLM technology. To find out more about why reaching industrial equivalent products with low viscosity resins is a faraway dream and higher viscosity opens the door to better part performance and a broader range of applications, be sure to download our white paper.

Interested in becoming one of the first in the world to take VLM technology under your wing? Our VLM Technology Adoption Program means you can:

- Be one of the first to discover the new VLM technology and see its full potential for yourself with real 3D printed parts

- Have a dedicated Additive Manufacturing applications engineer by your side to develop custom analysis and solutions

- Develop custom use cases for your company

Don’t miss out on the opportunity to make VLM your own and apply today!